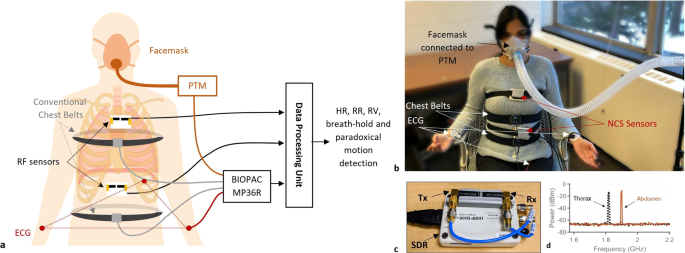

Wearable radio-frequency sensing of respiratory rate, respiratory volume, and heart rate | npj Digital Medicine

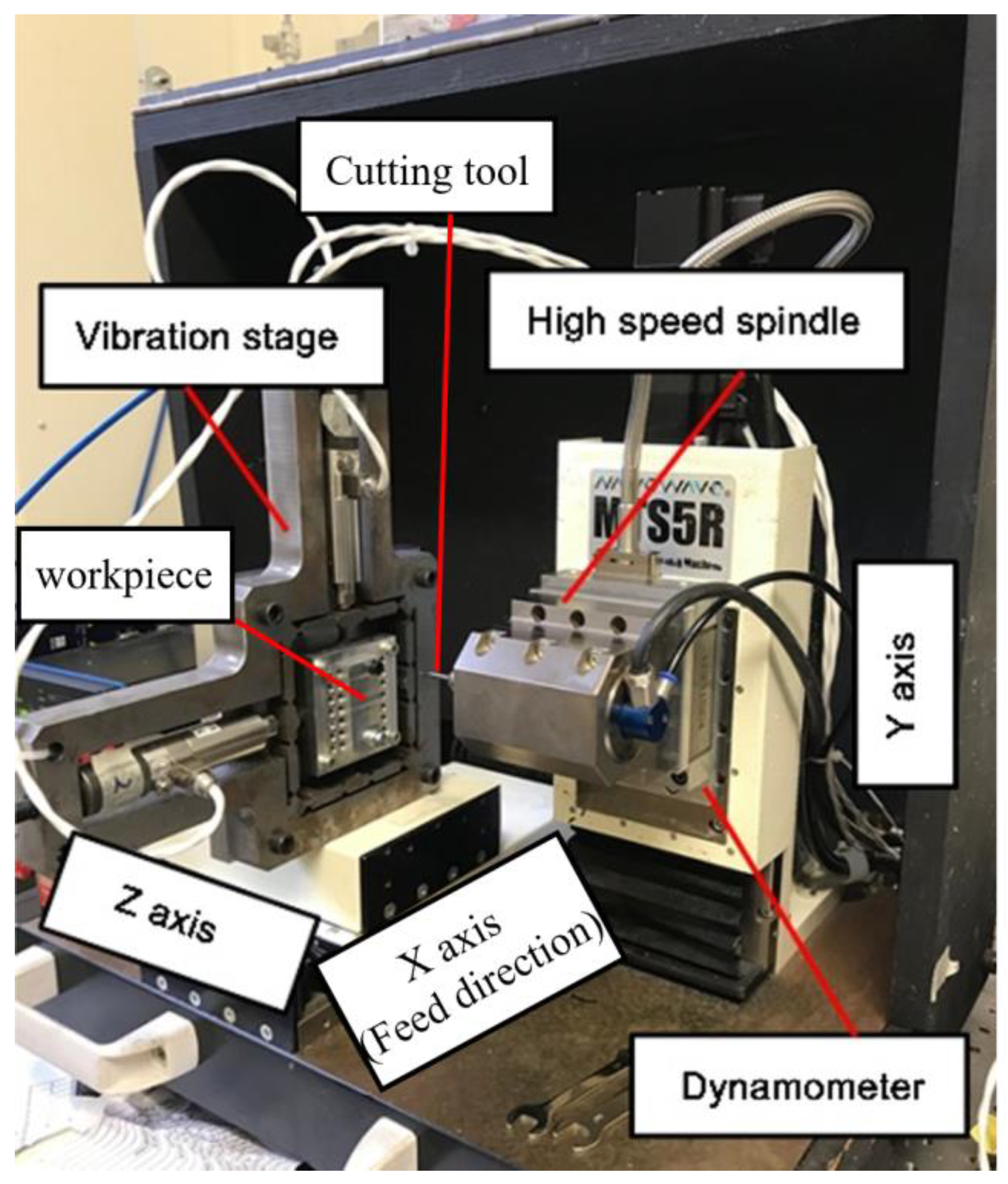

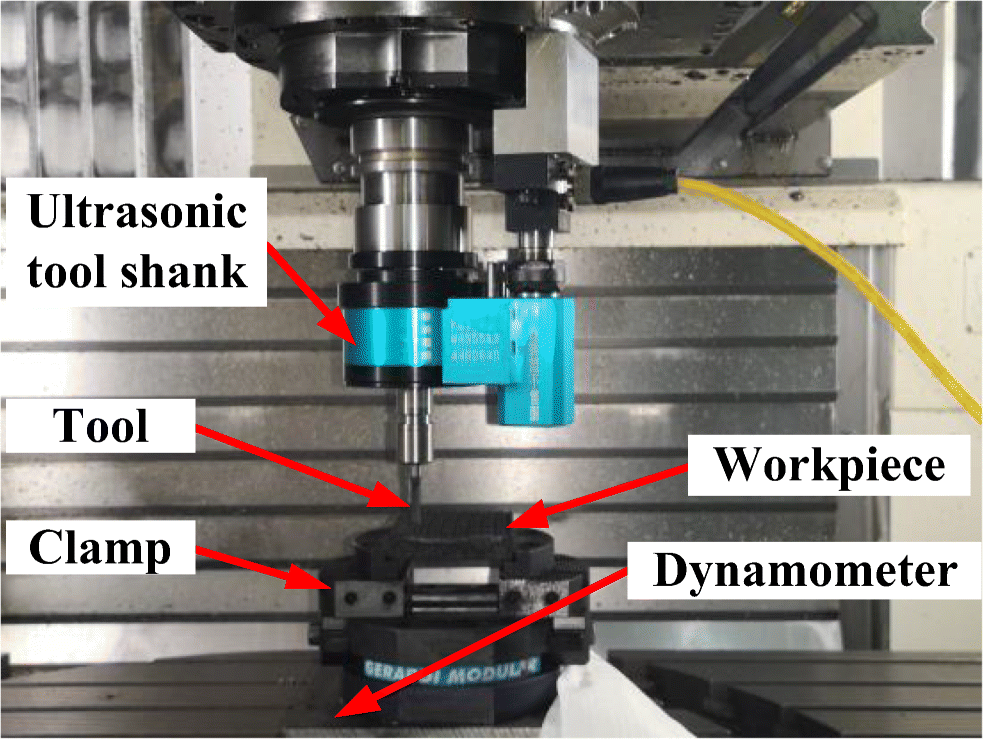

Micromachines | Free Full-Text | Investigation on the Tool Wear Suppression Mechanism in Non-Resonant Vibration-Assisted Micro Milling | HTML

Applied Sciences | Free Full-Text | Experimental Study of See-Saw Mode Nano- Vibration on Orifice-Type Restrictors | HTML

Correlation between vibration amplitude and tool wear in turning: Numerical and experimental analysis - ScienceDirect

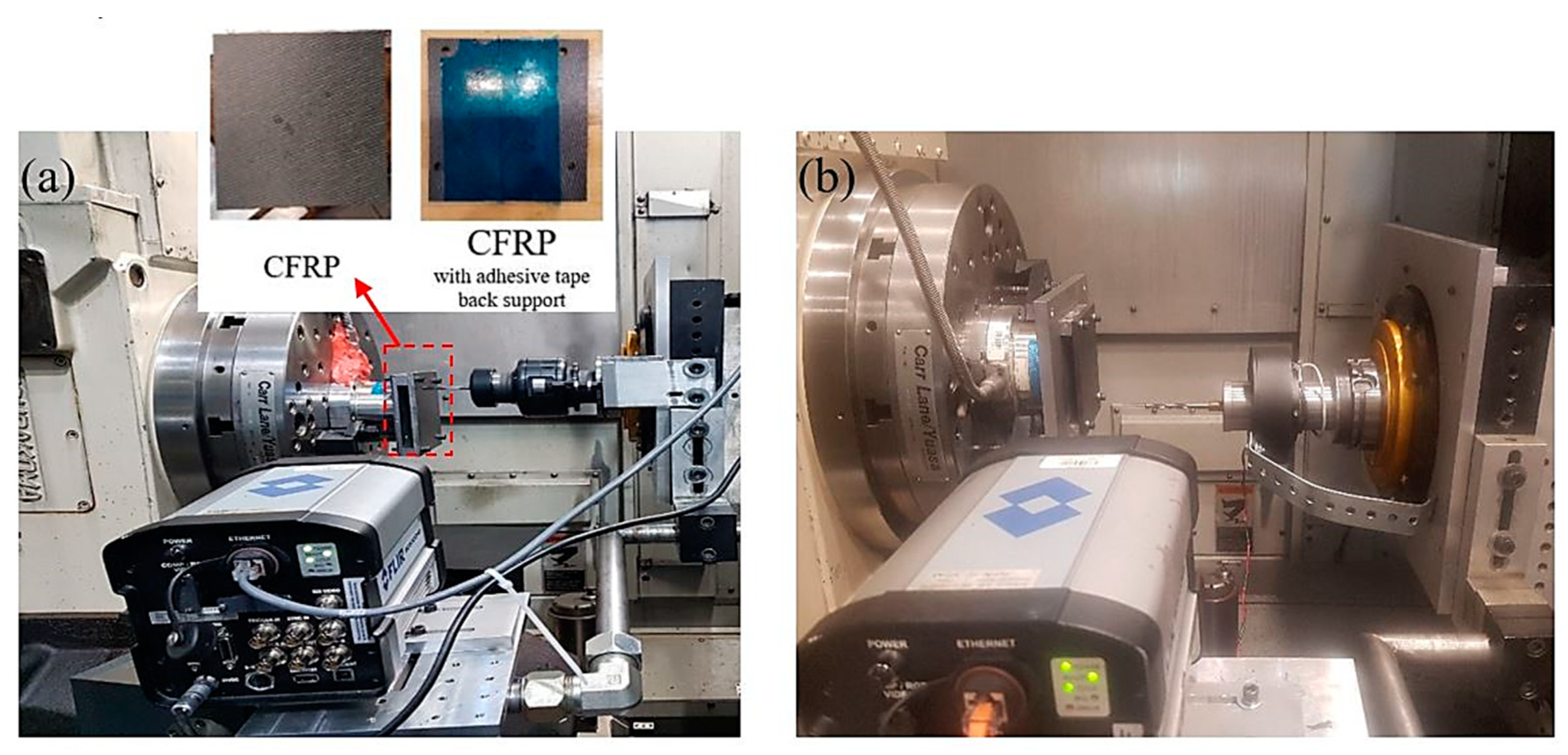

JMMP | Free Full-Text | Chip Morphology and Delamination Characterization for Vibration-Assisted Drilling of Carbon Fiber-Reinforced Polymer | HTML

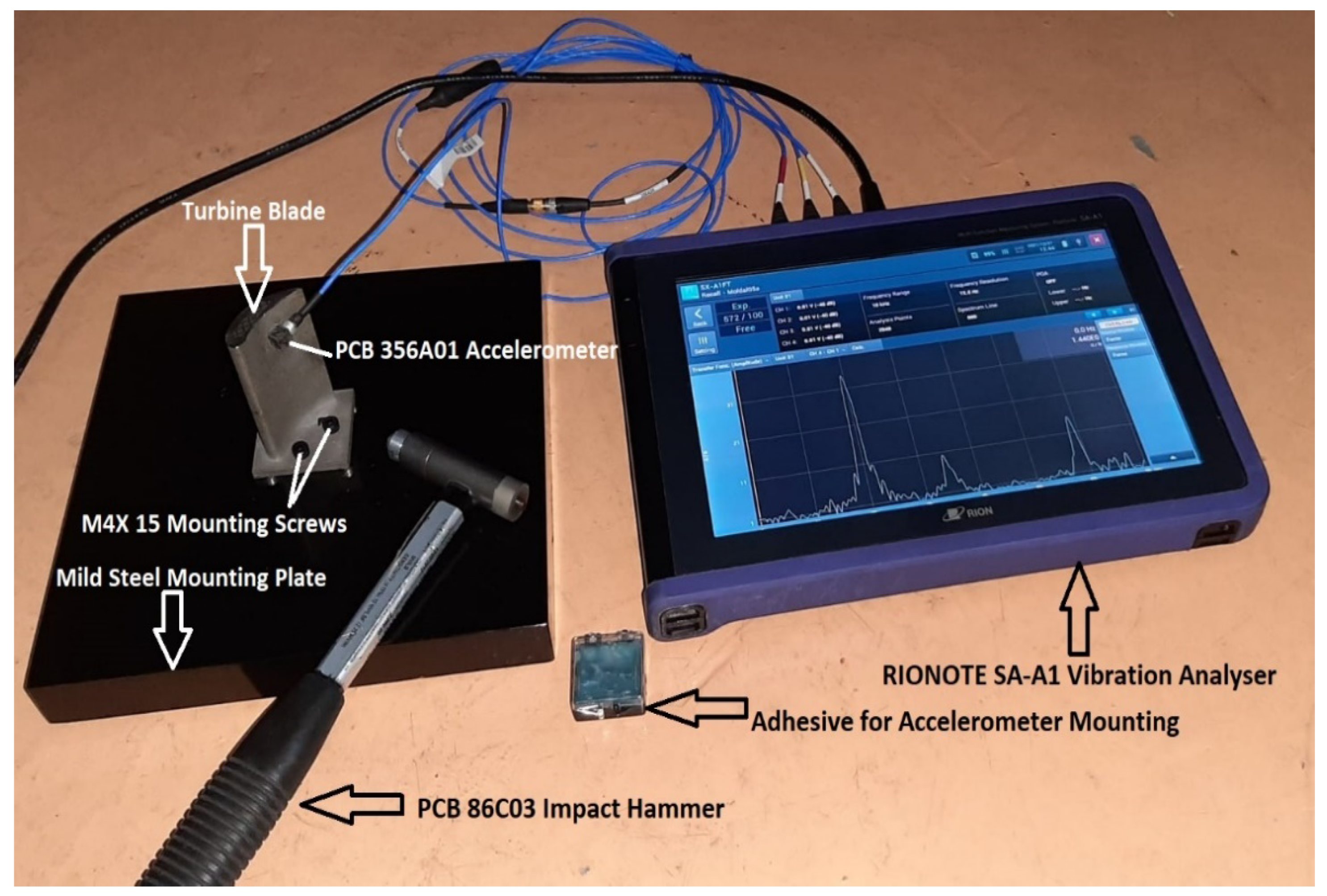

Simplified setup for the vibration study of plates with simply-supported boundary conditions - ScienceDirect

![PDF] Mathematical models of flank wear using vibration amplitude ratio in drilling | Semantic Scholar PDF] Mathematical models of flank wear using vibration amplitude ratio in drilling | Semantic Scholar](https://d3i71xaburhd42.cloudfront.net/30deaa1f70d577c181f565c225a230440dbc392d/4-Figure2-1.png)

PDF] Mathematical models of flank wear using vibration amplitude ratio in drilling | Semantic Scholar

Vibration-based tool wear monitoring using artificial neural networks fed by spectral centroid indicator and RMS of CEEMDAN modes | SpringerLink

Milling Tool Wear State Recognition by Vibration Signal Using a Stacked Generalization Ensemble Model

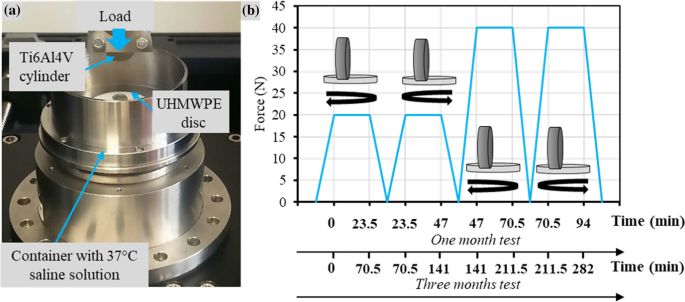

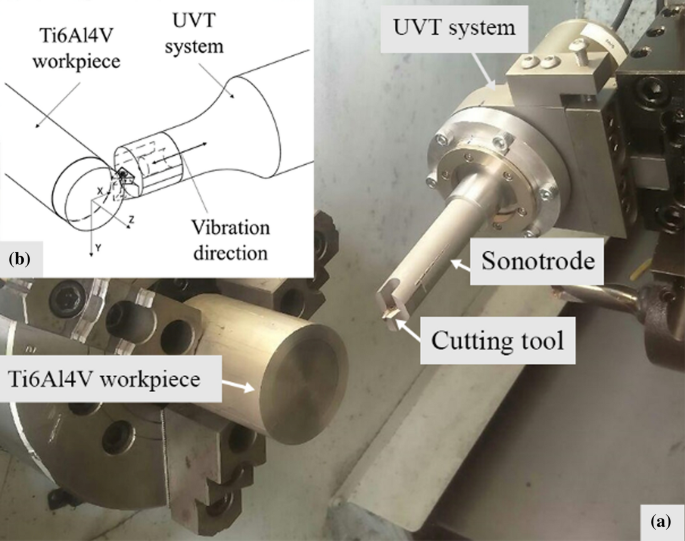

Wear Behavior of Ti6Al4V Surfaces Functionalized through Ultrasonic Vibration Turning | SpringerLink

Wear Behavior of Ti6Al4V Surfaces Functionalized through Ultrasonic Vibration Turning | SpringerLink

The Experimental Analysis of Vibration Monitoring in System Rotor Dynamic with Validate Results Using Simulation Data

Milling Tool Wear State Recognition by Vibration Signal Using a Stacked Generalization Ensemble Model

Correlation between vibration amplitude and tool wear in turning: Numerical and experimental analysis - ScienceDirect

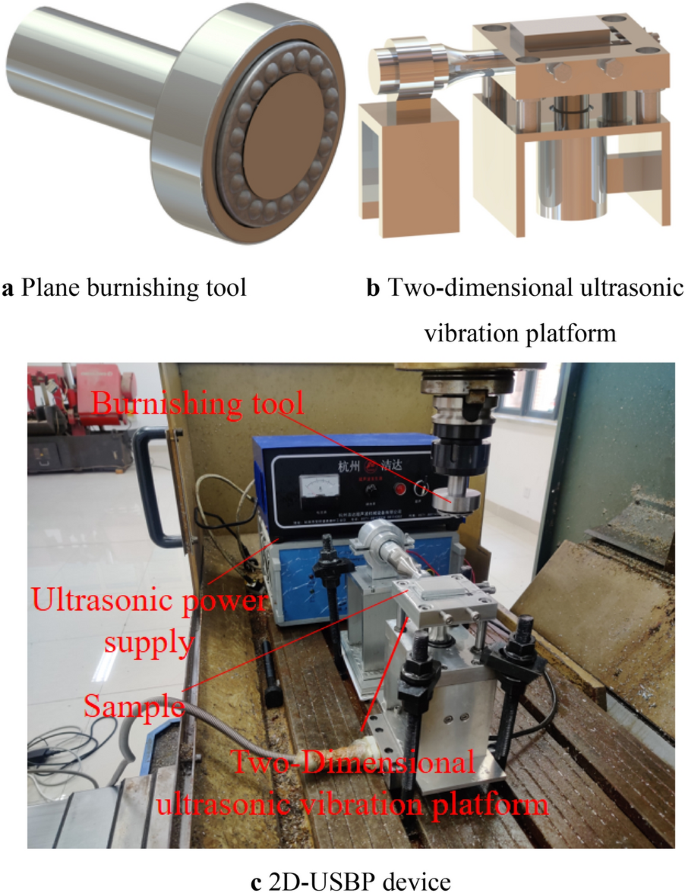

Investigation of Two-Dimensional Ultrasonic Surface Burnishing Process on 7075-T6 Aluminum | Chinese Journal of Mechanical Engineering | Full Text

Figure 4 | Experimental study on tool wear in ultrasonic vibration–assisted milling of C/SiC composites | SpringerLink

Experimental setup for measurement of tool vibration in X direction... | Download Scientific Diagram

Orthogonal Experiment Research on Tool Wear Characteristics in Diamond Cutting of Glass Soda-Lime | Scientific.Net

The experimental set up for testing whether two vibration motors could... | Download Scientific Diagram

Experimental set-up for wear contact between a cylinder and a rubber... | Download Scientific Diagram

Analysis of vibration signals to quantify displacement amplitude in the monitoring of vibration-assisted turning

Experimental study on machinability improvement of hardened tool steel using two dimensional vibration-assisted micro-end-milling - ScienceDirect